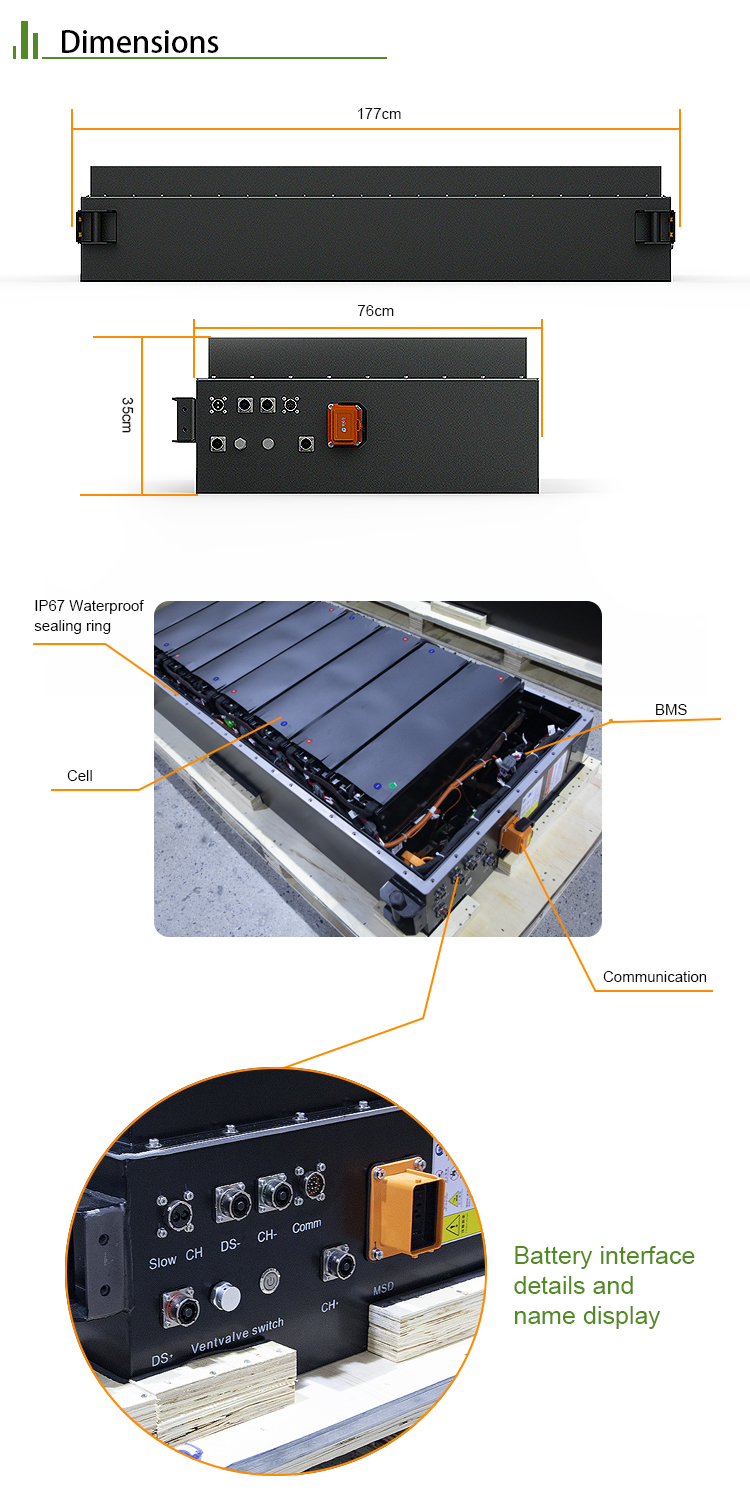

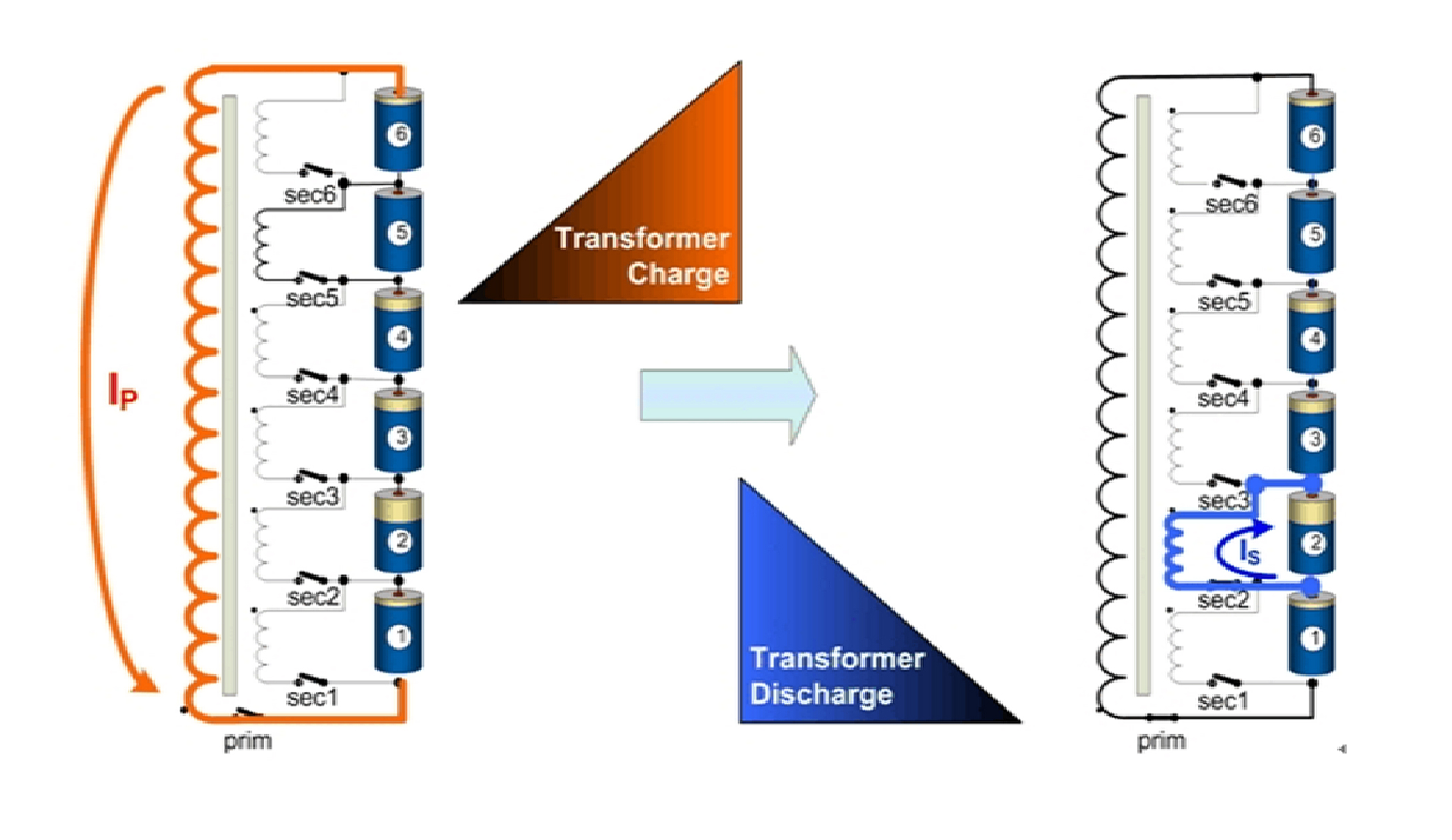

CTS has an experienced BMS development team. Our BMS uses passive balance by default. Active balance can be selected which can modify BMS parameters on site according to the actual application of customers, like CAN / RS485 communication protocol,

threshold parameters such as over / under voltage protection, high current protection, over / under temperature protection.