Place of Origin:

China

Brand Name:

CTS electric vehicle battery

Certification:

MSDS,UN38.3

Model Number:

EV lithium battery

Contact Us

| Parameters of 96v 400Ah Lifepo4 battery pack | |||

| No. | Items | Technical requirement | Note |

| 1 | Battery Type | LIFEPO4 | |

| 2 | Capacity(Ah) | 400 | @25ºC |

| 3 | Volatge | 96 | |

| 4 | Power(kWh) | 38.4 | |

| 5 | Weight(kg) | 337 | |

| 6 | Working Voltage range(DC V) | 75-109.5 | |

| 7 | Continuous discharge current(A) | 200 | @EOL,@25ºC |

| 8 | Peak discharge current(A) | 400 | For 30 seconds |

| 9 | Dimension (L/W/H, mm) | 1300*500*380 | |

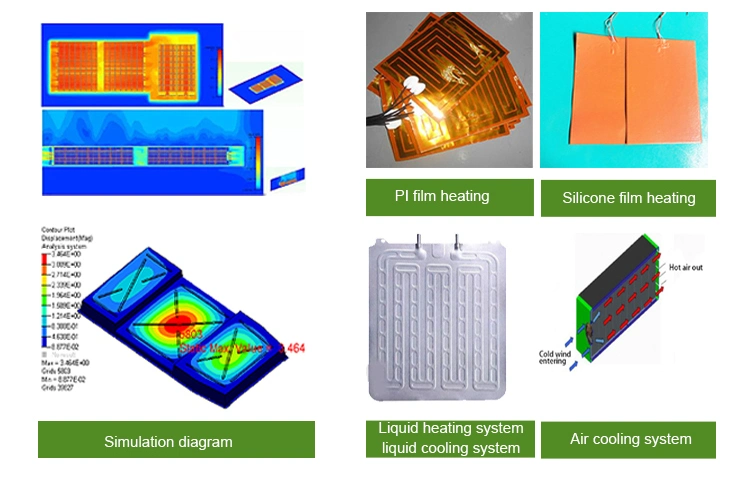

1.Lightweight and scalability

CTS systematically optimizes the cell design and electrical component selection. We select the lightest steel/aluminum

alloy and high-strength plastics,battery box and pack structure to reduce the volume and weight of the battery system

combined with CAE structural simulation analysis to ensure structural strength and improve energy density.

CTS uses standardized cells and BMS to build a 12V 24V 48V 72V battery modules. It can need different customer's

requirements by its excellent scalability to shorten the pack design cycle.

4.Test and Verification

4.Test and Verification

Send your inquiry directly to us